- Startseite

- Produkte

- DC/DC Wandler Bahn Eingang: 24 V, 36 V, 72 V, 110 V - Chassis mount.

- DC/DC Wandler Bahn Eingang: 24 V, 36 V, 72 V, 110 V - Open frame.

- DC/DC Wandler Bahn Eingang: 24 V, 36 V, 72 V, 110 V - DIN Rail.

- DC/DC Wandler Bahn Eingang: 24 V, 36 V, 72 V, 110 V - 16.8 kVAC Isolation.

- DC/DC Wandler Bahn Eingang: 750 V, 1500 V.

- DC/DC und AC/DC Wandler Kundenspezifisch.

- DC/DC und AC/DC Wandler Retrofit.

- DC/DC und AC/DC Wandler Medizin.

- USV Unterbrechungsfreie Stromversorgung.

- USB Charger Bahn.

- Applikationen

- Ressourcen

- Aktive Einschaltstrombegrenzung.

- Betriebstemperatur -50°C.

- Galvanische Trennung bis zu 16.8 kVAC.

- Isolationstest DC-DC Converter gemäss EN/IEC 60950-1 und IEC 62368-1.

- Mechanik.

- Power Boost - Doppelter Strom bei Überlast und Kurzschluss.

- Sicherungsautomat für DC-DC Wandler – wie auswählen.

- Wandler-Modul vs. Komplette Stromversorgung.

- Normen

- About intreXis

- Neuheiten

- Kontakt

intreXis AG Aktive Einschaltstrombegrenzung

At the input of each power-supply, bulk capacitors are needed for following reasons:

- Bypassing of converter-stage.

- EMC-filtering.

- Holdup time: Short interruptions of the input voltage supply do not cause any equipment failure (class S2 according to EN50155).

At power-supply turn-on, the bulk capacitors of the power-supply are completely discharged. The equivalent series resistance of the bulk-capacitors is way below 1 Ohm. This combination results in huge charging currents at power-supply turn-on.

These inrush-currents can reach hundreds of amperes, especially at higher input voltages (e.g. 110V-battery). The high inrush current can trigger a circuit breaker or burn a fuse unless you take precautions.

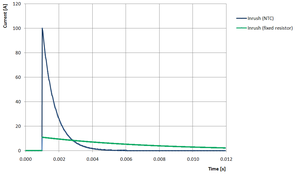

Classic solution to limit the inrush current by using NTC

Most power supply manufactorers use NTC's to limit the inrush-current. At the first power-supply turn-on, the NTC is cold and has a high resistance, which limits the current effectively. After a relatively short time, the NTC heats up due to its own internal dissipation and becomes low-resistant. Therefore, the power-dissipation during normal operation is reduced.

Advantages:

- Simple

Disadvantages:

- The effectiveness of this solution is very dependent on the ambient temperature: At high ambient temperatures, the inrush-current might not be limited sufficiently and at low temperatures, startup of the power-supply is not guaranteed because the NTC limits the current excessively (example: see table below with a 5 Ohm-NTC).

- At short interruption of the input-voltage (couple of 100 ms) the input capacitor is discharged but the NTC remains still hot and does not limit the current.

- The NTC dissipates and reduces the efficiency.

- During normal operation of the power-supply, the NTC heats up until it reaches steady state (approx. 110 °C). Therefore, the NTC heats up adjacent circuitry and the power-supply unnecessarily.

Ambient Temperature | NTC-resistance at turn-on | Inrush-current @ 110 VDC |

-40 °C | 68 Ohm | 1.6 A |

-20 °C | 27 Ohm | 4.1 A |

0 °C | 12 Ohm | 9.2 A |

+25 °C | 5.0 Ohm | 22 A |

+50 °C | 2.4 Ohm | 46 A |

+70 °C | 1.4 Ohm | 79 A |

intreXis AG active inrush current limiter technology

intreXis uses a fixed resistor to limit the inrush-current which can handle safely the high energy during the charging of the input capacitors. After the input capacitors have been charged, the resistor is bridged with a very low-resistant active component. When an interruption of the input-voltage discharges the input-capacitors, the active bridging component is deactivated and the inrush-current is limited again by the fixed resistor.

Advantages:

- The effectiveness of the solution is independent of the ambient temperature. It avoids false circuit breaker tripping and guarantees proper start-up of the power-supply.

- At short interruption of the input-voltage (couple of 100 ms) the input capacitor is discharged, the bridging component deactivated and the inrush-current is limited again by the fixed resistor.

- The active bridging component dissipates much less than the NTC and does not heat up the power-supply. The efficiency of the converter remains high.

Disadvantages:

- More complex.

The advantages of the inrush-limiter technology by intreXis outweigh the higher complexity of the circuit. The effectiveness and robustness of the circuit have been proven by field-experience and severe tests in the EMC-laboratory.

Download the intreXis Whitepaper SOLUTIONS TO LIMIT INRUSH-CURRENT

Applikationen

Was man mit unseren Stromversorgungen bauen kann.

Ressourcen

Was man über unsere Stromversorgungen wissen muss.

Normen

Was man von unseren Stromversorgungen erwarten darf.

Über Intrexis

Stromversorgungen für Bahnanwendungen

Die Leidenschaft für Technologie und Performance ist unser Antrieb, kontinuierlich noch bessere und effizientere Stromversorgungssysteme zu entwickeln. Das Resultat ist das derzeit umfassendste Portfolio von DC/DC Wandlern für Bahnanwendungen.